Top hammer XL: Expand the limit open up a world of possibilities

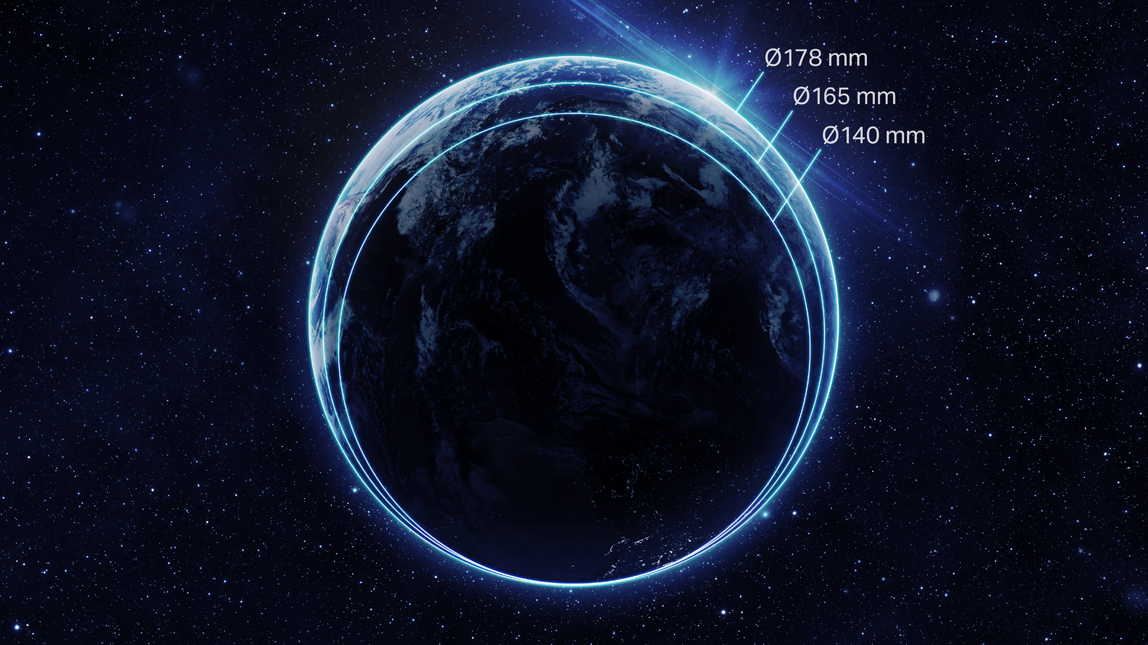

Sandvik’s latest innovation is proof that a seemingly marginal difference can make a significant change. The new, fully optimized drilling system consists of Pantera™ DP1600i drill rig, RD1840C rock drill and LT90 rock tools. It expands the limits for top hammer drilling, allowing you to drill blast holes from 140 to 178 mm (5½ to 7") with the top hammer drilling method. At the same time, you achieve faster, more fuel-efficient and more cost-effective drilling, with considerable savings in time, money, and CO2 emissions.

THE FUTURE IN TOP HAMMER DRILLING

“A key asset of the Top Hammer XL concept is that all three main components of the drilling system – the rig, the rock drill and the rock tools – have been reviewed, redesigned and mutually optimized. It truly works very well as a whole.” Jukka Siltanen, Product Manager, BU Rock Drills at Sandvik

TOP HAMMER XL

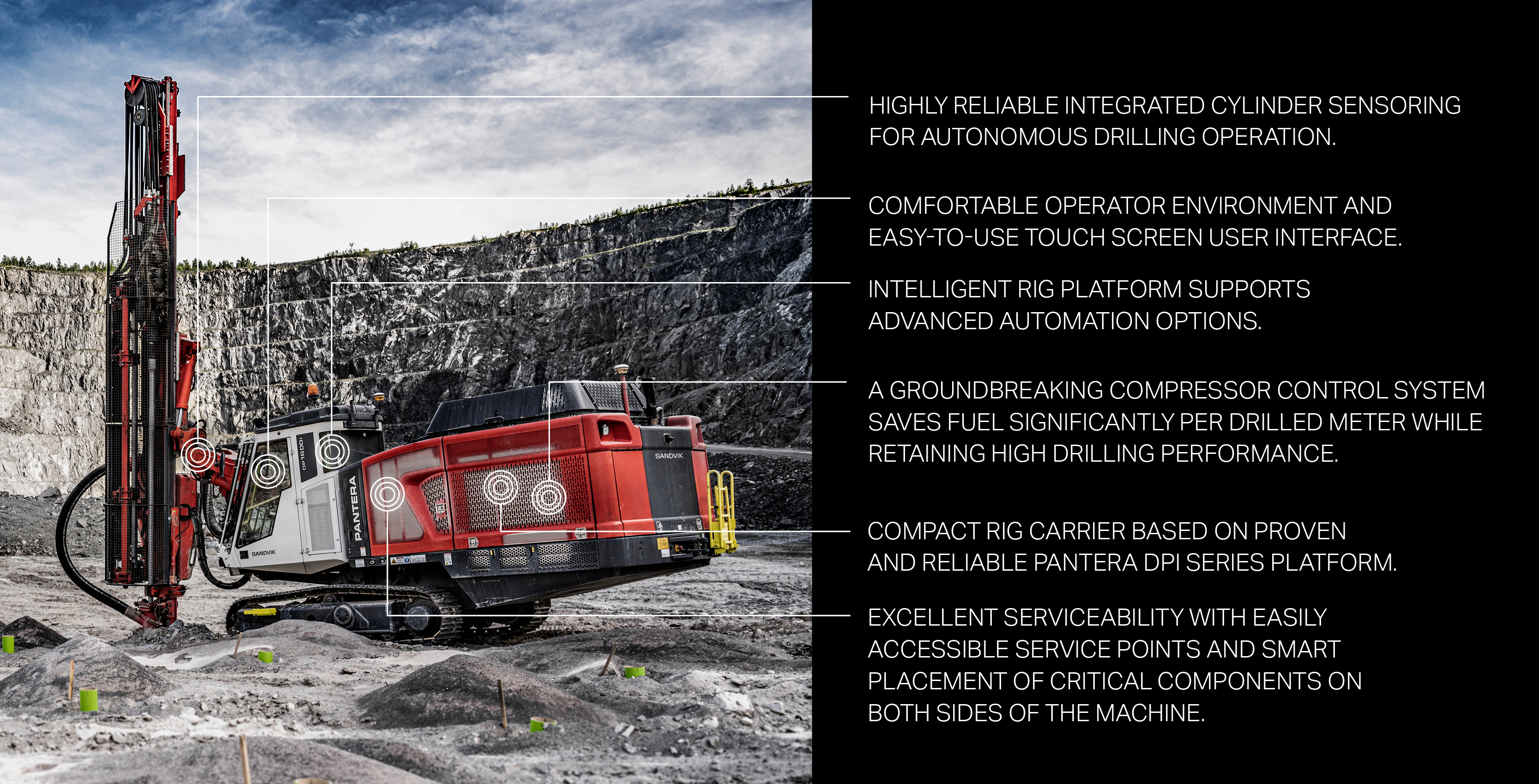

PANTERA™ DP1600i

Pantera™ DP1600i is the newest member of the Pantera DPi series family of intelligent top hammer drill rigs. It is characterized by high penetration rates and advanced automation options for data-based fleet management and drilling performance optimization. It fits perfectly for production drilling in large quarries or open pit mines.

Read more about Pantera™ DP1600i

The new Pantera™ DP1600i is based on the reliable and proven Pantera DPi series platform, with upgraded key components to meet the needs of the Top Hammer XL system. Together with the powerful RD1840C rock drill and robust LT90 rock tools, the end result is extreme capacity for a larger hole size, without increasing the actual physical drill rig footprint. With a long track record and proven performance in top hammer drilling, the Pantera DP1600i will bring a true productivity boost to surface mining customers, featuring next-level technical solutions that provide power, fuel economy, more uptime hours and smooth flow of operation.

| Technical data | |

|---|---|

| Hole size | 140-178 mm (51/2”–7”) |

| Drill steel | LT90, 25 m (82 ft) |

| Drifter | RD1840C |

| Percussion power | 49 kW (66 hp) |

| Engine type | Caterpillar C11, Tier 3 / Caterpillar C9.3B, Stage 5 |

| Engine Power | 287 kW (385 hp), 1800 rpm / 280 kW (375 hp), 1800 rpm |

| Air capacity | 14 m³ / min, 490 cfm, twin-pressure compressor |

| Operator cabin | Ergo with air conditioning |

| Weight | 23,000 kg (50,706 lbs) |

Sandvik has a long track record and proven performance in top hammer drilling. Therefore it was natural for us to upgrade the existing, well-known platform to the next level for this new solution.

JARNO VIITaNIEMI

Product Manager Surface Drilling at Sandvik

TOP HAMMER XL

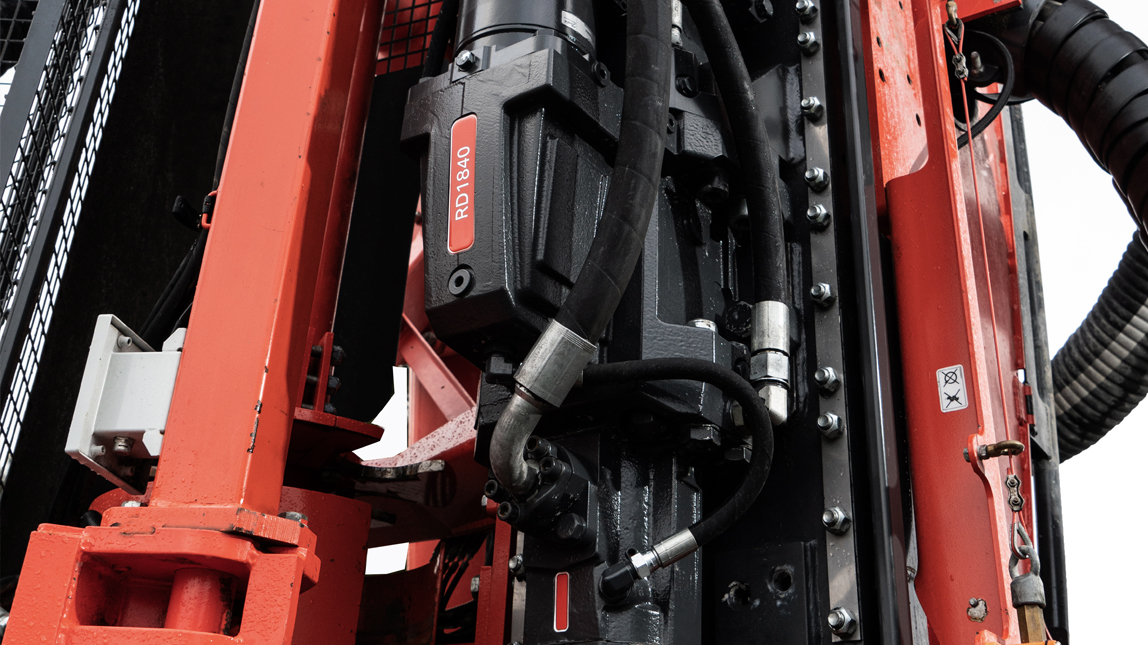

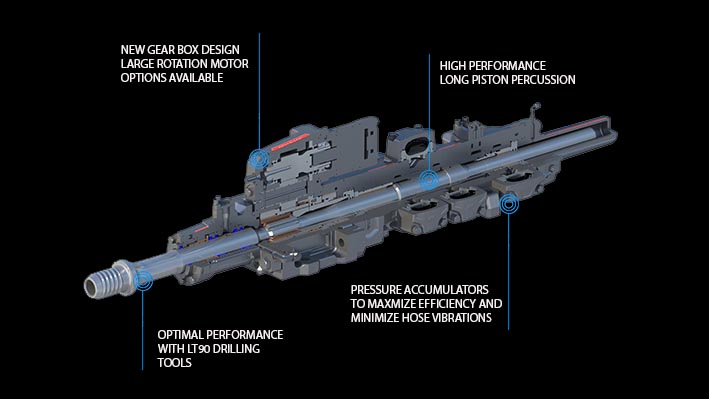

RD1840C ROCK DRILL

Read more about the Rock Drill RD1840C

| Technical data | |

|---|---|

| Hole diamter | 140–178 mm (51/2”–7”) |

| Power class | 49 kW |

| Percussion rate | 39 Hz |

| Operator pressure percussion | 140-280 bar |

| Rotation (max) | 150 bar (630cc) /110 bar (800cc) |

| Rotation motor size | 630 cc / 800 cc |

| Drill steels | MF tube LT90 |

| Shanks | Ø 80 mm / LT90 |

| Weight | 570 kg (1255 lbs) |

A key asset of the Top Hammer XL concept is that all three main components of the drilling system – the rig, the rock drill and the rock tools – have been reviewed, redesigned and mutually optimized. It truly works very well as a whole.

JUKKA SILTANEN

Product Line Manager, BU Rock Drills at Sandvik

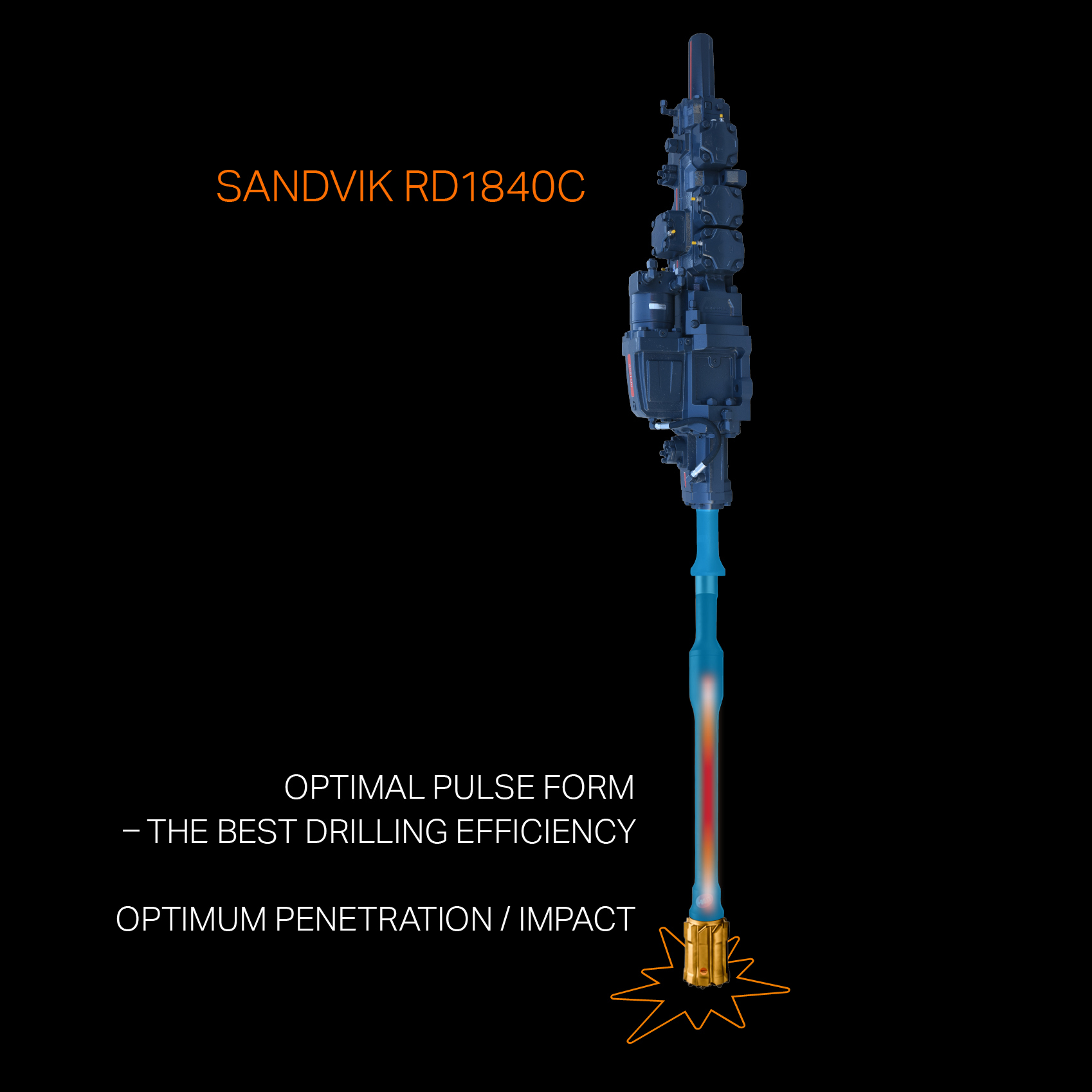

INNOVATED TO INCREASE YOUR PRODUCTIVITY

Top Hammer XL is designed and innovated to maximize the power of your drilling.

HOW DOES IT WORK?

- Long piston technology provides high impact energy with optimal pulse form

- The length of the pulse depends on the length of the piston

- Rock drill and tools are dimensioned to work together, which offers the best possible drilling dynamics and rock breaking efficiency.

TOP HAMMER XL

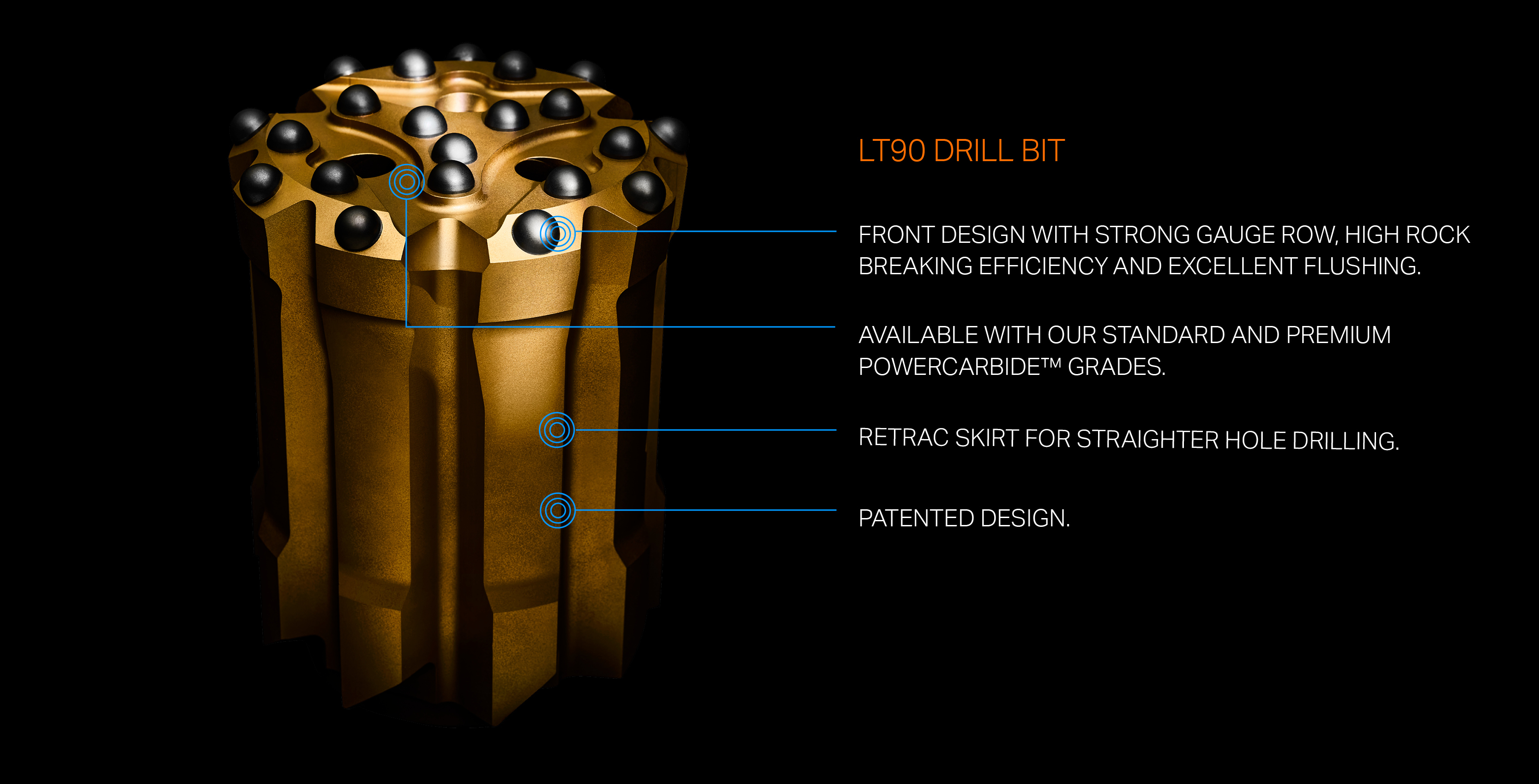

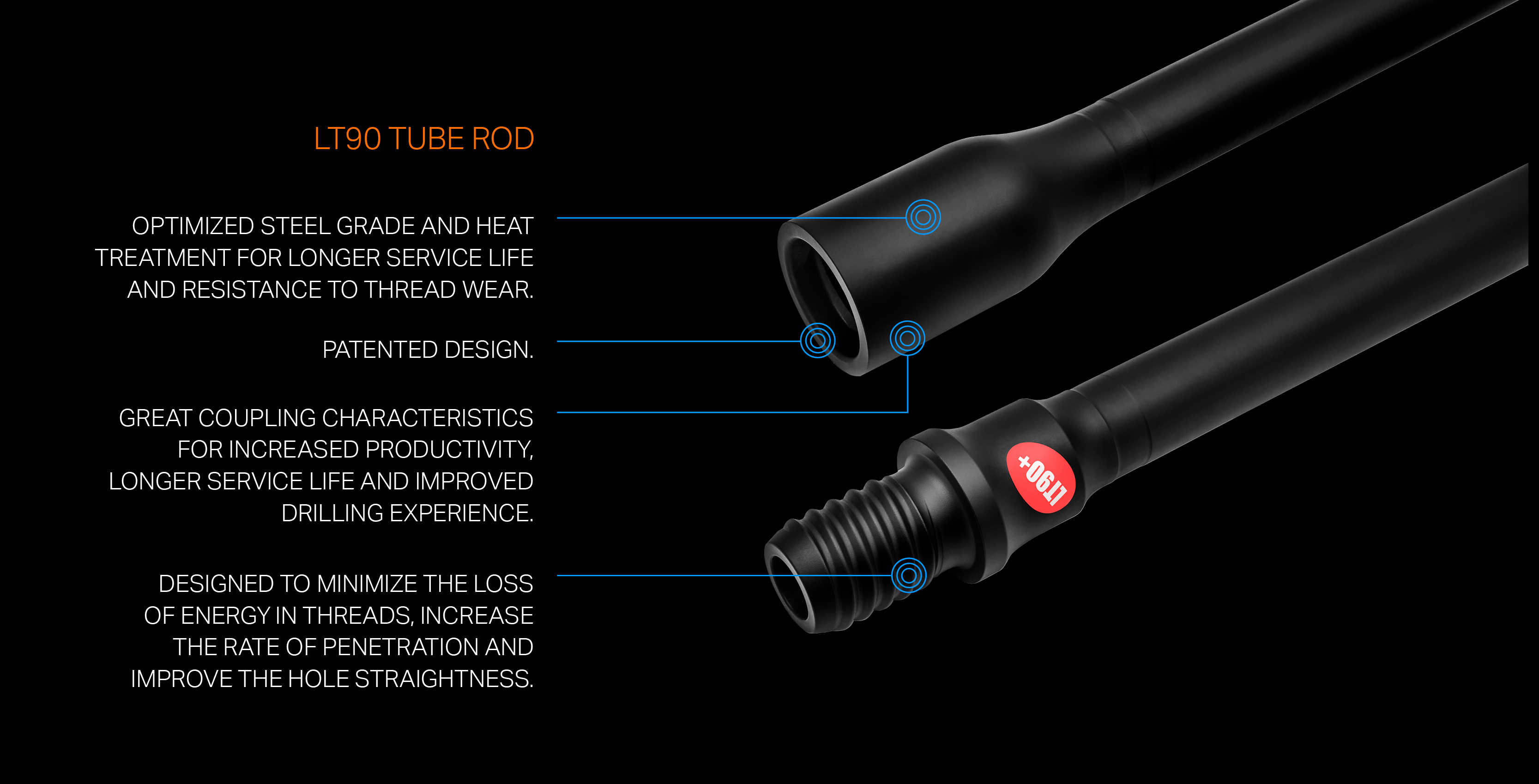

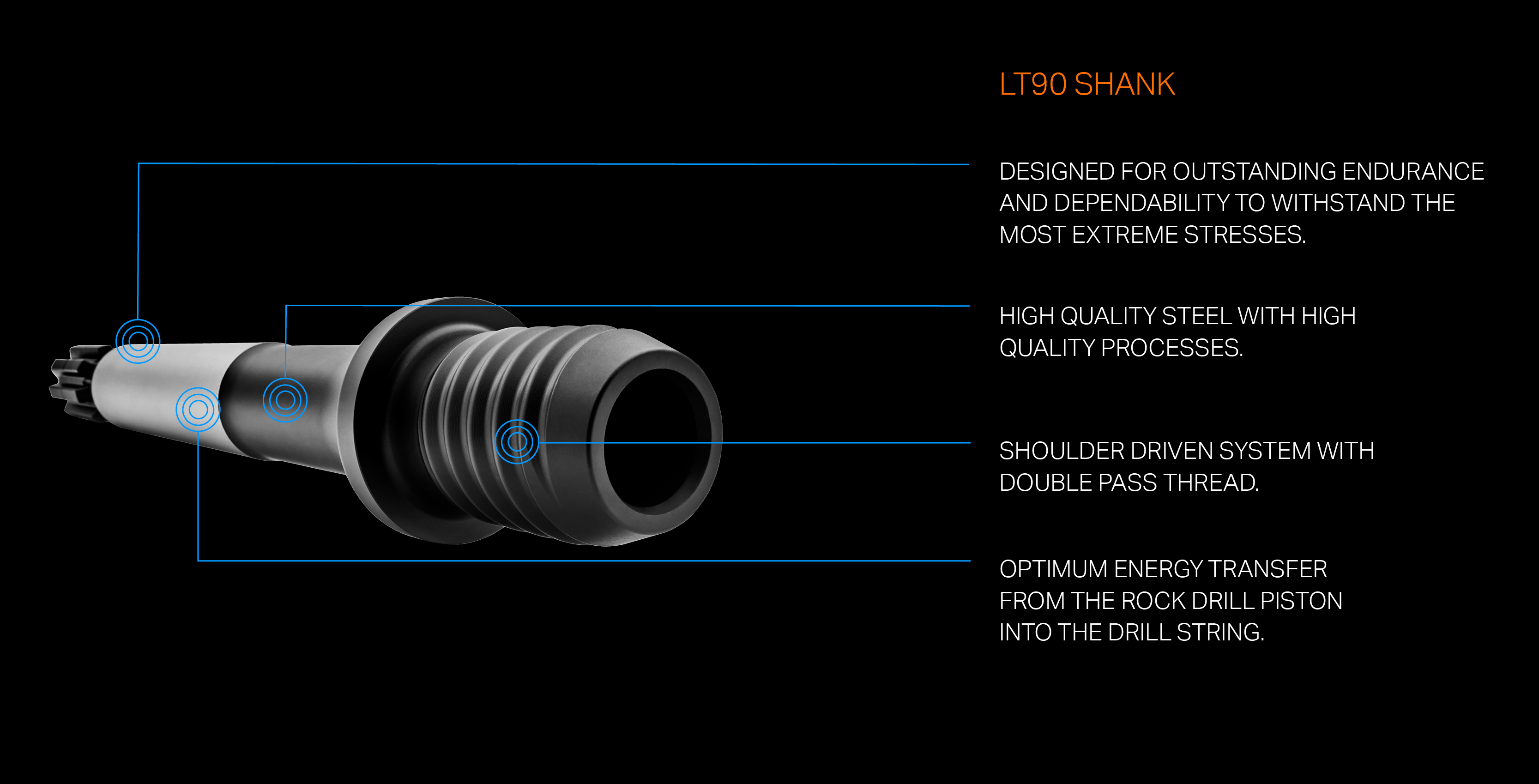

LT90 ROCK TOOLS

Our LT90 rock tools are developed to perfectly match the drill rig Pantera™ DP1600i and the rock drill RD1840C. The tool system, manufactured in Sweden, offers the best possible drilling dynamics and rock breaking efficiency. The patented optimized design increases your productivity, improves the hole straightness, provides great coupling characteristics and longer tool service life. All in all a much better drilling experience.

Read more about the LT90 rock tools

* Calculations presented on this page are estimations based on field test results under specific controlled conditions. The results may vary depending on actual drilling conditions and thus Sandvik does not guarantee the same outcome in any other condition.